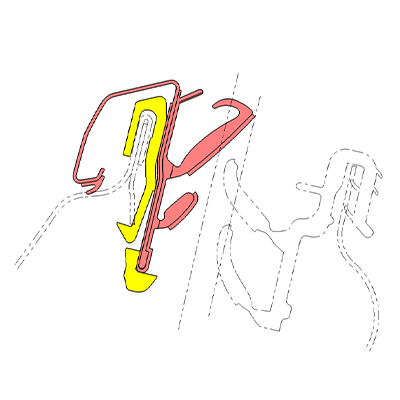

WINDSHIELD GLASS MOLDING

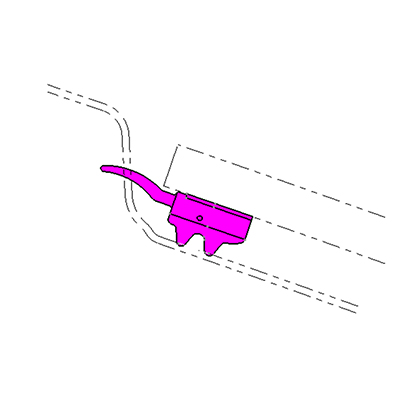

● Assembly Location

Installed between the vehicle's windshield glass and the panel

● Part Function

Reduces the infiltration of water leaks, and noise through the glass

Installed between the vehicle's windshield glass and the panel

Reduces the infiltration of water leaks, and noise through the glass

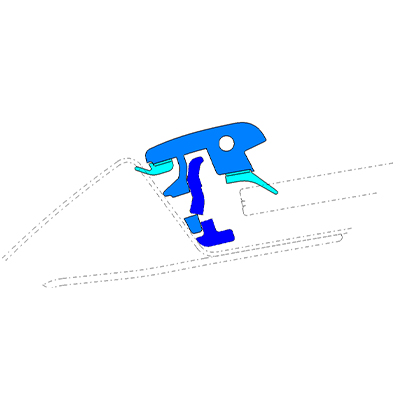

Assembled between the side outer panel and the windshield glass

Acts as a RAIN GUTTER, blocking internal and external elements, thereby enhancing the vehicle's appearance

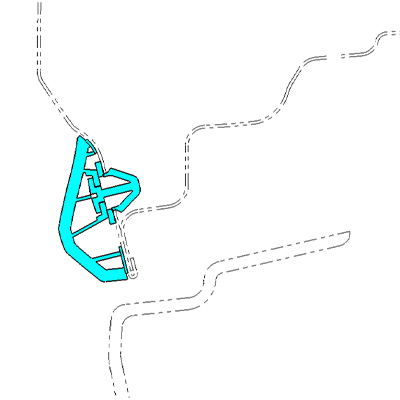

Installed on the side outer panel

Ensures excellent compatibility with related parts and prevents water from entering the interior through its watertight sealing feature

Mounted on the door's inner panel

Improves the flexibility of the door glass operation protects the glass from breaking, and prevents the entry and accumulation of dust and foreign materials

Installed on the door's outer panel

Enhances the flexibility of the door glass operation prevents glass breakage, and blocks the entry and accumulation of dust and foreign materials

Assembled at the bottom of the door's outer panel

Prevents damage to the panel and door from external impacts, enhancing the vehicle's appearance

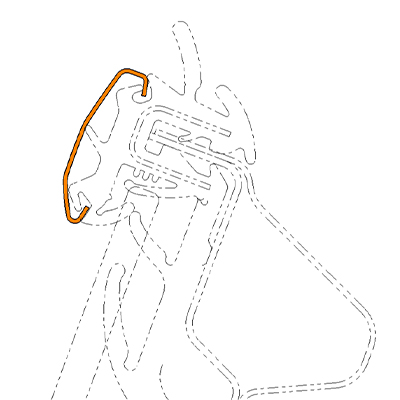

Installed between the vehicle's ceiling side outer panel and the roof panel

Conceals the panel joints, improving the aesthetic appeal of the exterior

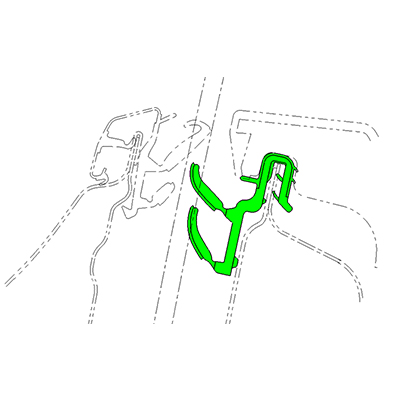

Mounted on the door frame panel

Provides a watertight seal to prevent water from entering the interior, while also enhancing the vehicle's appearance

Installed on the door frame panel

Improves the exterior appearance (enhancing exterior quality)

Assembled between the trunk lid panel and the rear frame panel

Enhances the exterior appearance (improving exterior quality)

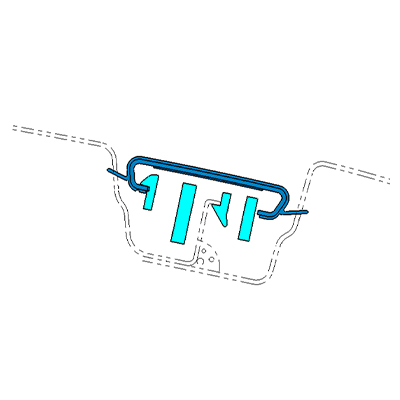

Installed within the vehicle's inner panel

Drains rainwater from outside, preventing it from entering the interior and directing it out of the chassis

As the exterior appearance of newly released vehicle models became more luxurious, there was a need to apply a glossy black color to the door belt's exterior for color consistency. This was achieved by attaching an Exterior Trim Film (ETF) to the exterior during the door belt extrusion process, successfully implementing the color without a separate plating process

70µm

Application of the film to the door belt's exterior to achieve a glossy black color

Although the technology to apply a glossy black color to the door belt's exterior by attaching ETF was developed, problems such as wrinkling or cracking could occur depending on the door belt's design. To reduce these defects, a technology was developed to deposit a thin film directly onto the SUS material itself, allowing for the implementation of the black color without the need for plating or ETF.

A technology that deposits solid particles onto a material in a vacuum state to form a thin film using physical methods.

Achieving a glossy black color on the door belt's exterior, simplifying the process compared to the ETF specification.

With environmental issues becoming a concern in various countries including the USA, Europe, and Japan, the automotive industry is actively pursuing vehicle lightweighting to improve fuel efficiency. Using aluminum instead of steel can achieve a weight reduction of more than 60%.

7.75 / 2.68

Weight reduction and cost saving, improved formability, minimized spring back effect, and increased recyclability

To comply with EU end-of-life vehicle recycling regulations, door belts are being developed using thermoplastic materials that are easy to recycle. As these do not incorporate a metal core, continuous sizing molds are arranged to prevent deformation and enhance the formability of the product.

Cost reduction due to simplified manufacturing processes, component lightweighting, and enhanced recyclability

To meet the trend of luxury enhancement and quality improvement in automobiles, high-gloss injection molding is applied to door frame garnishes. Unlike the conventional process requiring a painting process to achieve a glossy black color, the painting process is unnecessary when using PMMA for high-gloss injection.

Often used as an alternative to glass, it is known for being lightweight, transparent, and durable.

Process simplification, cost reduction, and reduced defect rates.

To improve the exterior color harmony of DLO molding, aluminum extrusion methods are being examined.

A process where a billet is pushed through a die under high temperature and pressure, shrinking its cross-section to produce a profile.

A process that forms an oxide film on the surface of a product to prevent oxidation and enhance durability.

Lightweight and high strength, able to maintain strict tolerances, and offers a variety of surface finishes

Thin and long products are prone to defects such as sink marks and flow marks during injection molding, and warping or cracking due to residual stress after molding. To improve this, a new method has been developed

A technique where gas is injected during molding to improve the flow of the resin, creating hollow spaces inside the molded item, which also aids in lightweighting

Decreased rate of exterior quality defects, lightweighting due to gas channels, and cost reduction

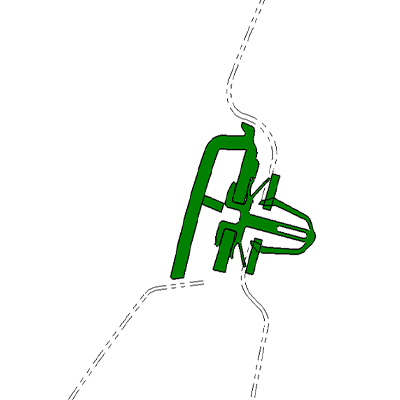

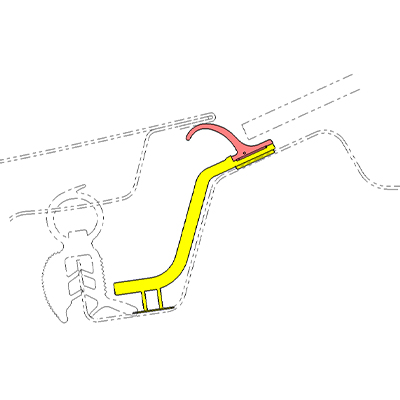

Traditional molding could only extrude in a uniform cross-section, limiting the range of part applications. However, variable extrusion technology allows for up to three different shapes to be implemented, expanding the product's application range

A feature that prevents rainwater wiped by the front wipers from overflowing to the side windows, thus not obstructing the side view during rain

Improved exterior aesthetics, application of rain gutter function to glass molding